Ferrari F40 - The legend of the thin paint

We’ve all heard the line: “The paint on the Ferrari F40 is so thin, you can see the carbon fiber weave beneath it.” I remember hearing this many years ago, and it always came up in conversation during our obligatory late-night coffee runs.

The car guys would comment on how ‘pure’ the F40 is, and that it’s essentially a race car for the road. The paint needed to be thin to save weight – making the carbon fiber weave visible.

Did we actually understand what this all meant? It’s easy to understand a thin coat of paint, but what the hell did we know about weaves and this fancy material, and why it should be visible? To answer this, we have to dig deeper and delve into the different factors involved in making a supercar out of the space-age material, carbon fiber.

The facts – What causes the weave texture?

The F40’s coating may be thin to reduce weight, but even if we used a standard paint process used during the coating, the carbon weave would, most likely, still be visible. That’s because carbon fiber panels aren’t smooth to begin with, and I will do my best to explain why.

Technically speaking, if the designers and engineers wanted a ‘smooth’ surface finish on the F40, the car would weigh more. How much more exactly? Approximately the weight of a 2-liter bottle of cola. In most cases, a couple pounds or kilos isn’t a lot of weight but in race car terms, every gram counts.

This ‘smooth surface’ also means a higher cost in manufacturing. To find out why, let’s refer to the wonderful world of automotive bodywork.

Smoothening out body panels is an important step before painting a car. By using different sanding techniques, the goal is to make a panel as straight and as true as possible. Usually, this is done by coating a panel with a high-build primer and then sanding it smooth. In a perfect world, stripping off any old paint would reveal a straight metal form underneath during a car restoration. But there’s many reasons – ranging from metallurgy, climate and accidents – why the bare metal will most certainly not be straight. So, to actually make it straight, you may need a coat of high-build primer, and in some cases, body filler. The bulk of the time spent restoring the body of a car is in this process.

“Now, how does this relate to the F40? I mean, you’re talking about stone-age vehicles built with heavy, rusty steel. The F40 is an alien space craft formed from a mythical black material mined from another planet and held together with green ooze.”

Well, to understand how this relates to the visible weave of the F40, let’s switch gears a little bit and learn about composites!

By definition, a composite is made with two or more materials with significantly physical or chemical properties. When combined, they create a new material with characteristics different from the original single material.

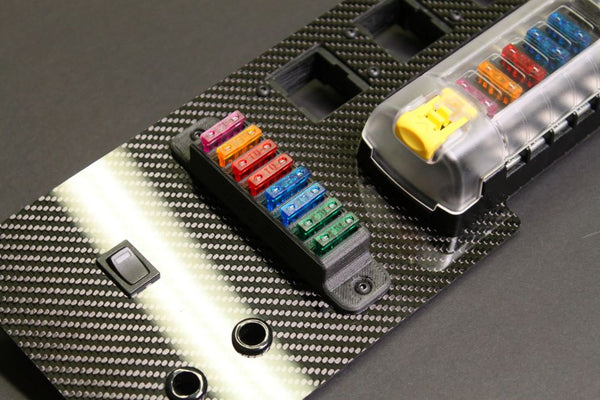

In our case, the body panels are made of carbon fiber fabric, and epoxy resin. These materials on their own are inadequate as automotive body panels. In its ‘dry’ state, carbon fiber looks more like a material you’d use sew a T-shirt, than something used to make a fender. And epoxy resin, well, is a liquid. When you combine the two, these materials result in an ultra -tiff and light-weight super material! There are many ways to combine carbon fiber fabric, and epoxy resin, but we’ll get into that another day. One of the key things to understand is, epoxy, when introduced to a hardener, goes through a chemical reaction to reach its ‘cured’ state.

Composite vs. Metal

A cured composite is now a rigid material made of carbon fiber fabric and epoxy resin. To understand where we get the famous ‘weave’ pattern under the F40s’ paint, let’s make a comparison.

Take a regular steel fender, and compare it to one made from carbon fiber. What’s the difference between the two? Yes, the carbon fiber one is much lighter and won’t dent or rust. The main difference, which we touched on above, is the carbon fiber panel is composed of two different materials. The steel fender isn’t considered a composite even if it’s alloyed with other elements.

Why do composites have texture?

Simply put, two different materials, with unique properties, will expand and contract at different rates and different values when exposed to elevated temperatures. Let’s refer back to our single-material steel fender. Since the steel is refined and free of defects, it’ll expand evenly when exposed to heat. If we look at the carbon fiber fender, we have a problem. Now we have two completely different materials reacting to the same temperature change. Carbon fiber, which is known for being one of the worlds stiffest materials, has virtually no ‘stretch’. The epoxy, which is now cured after going through a chemical reaction, is not nearly as stiff as the carbon. In fact, after an initial cure, epoxy will continue to cure for weeks and continue to shrink. These differences in expansion and contraction result in the visibility of the fiber weave. It may not be obvious straight out of the mould, because the epoxy continues its curing process and will shrink slightly. This shrinking is what causes the surface distortion, which is more apparent on gloss surfaces than it is on satin surfaces.

An important decision

So, by this point, the pieces are starting to fit together, right? Our question is, why is the weave visible under the F40’s paint? The answer has proven to be much more complicated than you’d think.

Let’s focus on our carbon fiber fender again. The epoxy’s been impregnated into the carbon fibers and it’s now considered a composite. It’s time for the engineers to decide how to finish the panel. After the carbon fiber is ‘layed up’ in the mould and cured, it’s de-moulded and ready for trimming. After the component is trimmed, it’ll be sent off for painting.

Since the F40 is race inspired, function is prioritized over form. Instead of coating the panel with a filler primer to hide the surface distortion, the car designers most likely decided to save the extra weight and opt for a thin interface coat followed by colour. These layers of paint are not thick enough to even out the low spots to the high spots of the weave, so we are left with a fully painted component showing a weave.

An attribute for appraising

Back in the day, the carbon fiber weave on the F40s may not have been as visible off the production line but as the years go by and the carbon fiber goes through more and more temperature cycles, that weave becomes more apparent. This attribute is used by collectors and aficionados to determine whether a panel’s been painted or repaired.

It’s virtually impossible to sand or prep the original surface without flattening the tops of the fiber weaves, and repairs will most likely be coated with a filler primer to smooth the panel before painting it.

Advancements in composites

Ultimately, the famous line we first mentioned is indeed true. But the reasoning behind it is more than just “thin paint, because race car.” Today when clients purchase multi-million-dollar super cars, they’re expecting a car that performs well but also looks like a show car – paint finish included.

With all the advancements in composites and the use of pre-preg materials, there’s different ways to achieve a smooth carbon fiber finish that don’t add more weight and cost.

We now have the ability to apply the filler primer in a very similar way that the carbon fiber reinforcement is applied. This primer, or ‘scrim’, is applied directly onto the mould in a solid state. This method saves time and material and is more efficient than spraying. The scrim material is engineered with the correct ratio of primer, so nothing’s lost to overspray. With the use of autoclaves and the chemical compositions of epoxy resin, composites can be manufactured more efficiently and with better physical properties – including those related to surface finish and visual appearance.

There’s something exciting about seeing what’s underneath the skin of a car with a hardcore reputation. It reminds us that the F40 was meant to be thrashed on the racetrack and not left in a garage to look pretty. Although, the F40 does that well too.

Matt

Photos in this article are used with permission from Damian Butt at TheCarGuys.TV